I bet at least some of you experimented a little with invisible ink when you were young.

Lemon juice was my chosen method, because it was easy, but mainly because I didn’t really know anything else. It dried clear, but heating the paper brought out the writing or drawing in brown. It was good, schoolboy fun, but I haven’t really given it much though until recently, when I was considering possible options for a design challenge involving hidden messages.

A hidden message can impart a sense of mystery and involvement – as long as your audience knows it is there and can manage to reveal the information somehow. That’s half the trick; if someone doesn’t know the message is there, and if it is hidden effectively, it will probably never be found at all – in which case why bother making it in the first place? If they do know it’s there but don’t know what to do to reveal it that’s almost as bad, and quite frustrating for the would-be reader.

The traditional methods of making a hidden message on paper are quite simple. A 50/50 baking soda and water mix will dry to be invisible on paper, but painting concentrated grape juice over the surface will cause a reaction that colours the baking soda-treated areas. Vinegar as ink and a red cabbage solution as the developing reagent also works, and for those looking for a more specifically cold war-style method, East Germany’s Stasi used cerium oxalate and developed messages using solutions containing manganese sulphate and hydrogen peroxide – somewhat less appetising, but presumably very effective.

The lemon juice trick I used as a kid is probably the easiest of all. In short, the acid in the lemon juice damages the fibres in the paper. Not in a way that’s obvious when dried, but when heat is applied by, say, ironing the paper, or by holding it near a candle flame (carefully, ok?) the ‘inked’ areas are primed to darken and scorch much sooner than the untreated paper. Clever, huh? In fact any acidic liquid will do, but the stronger the better. This means limes trump oranges, hands down.

That’s all fine for kitchen table fun, but you can’t put lemon juice through an inkjet printer, and you definitely can’t get your local litho print firm to clean out a press and squeeze citrus fruit into the ink reservoirs! (If you can, I really want to see photographic evidence.)

But there are other ways to print invisibly. At the basic level, how about black on black? This could be black ink (or toner) onto black paper; the difference between the two black tones – ink and paper – will normally be not be so clear that it is obvious on first glance, but still be enough to detect on closer examination. You can achieve the same kind of result on normal plain paper with a ‘single colour’ black and a rich black. The first is what you get by printing just with the black plate in commercial four-colour offset work, or with just the black cartridge in an inkjet printer, if your device’s print driver doesn’t override how colour is output. It is black, but not a truly dense, velvet-at-midnight black. The second, a rich black, is made from black plus equal amounts of the other inks as well, specifically the magenta and cyan. Process yellow is actually pretty weak, so it doesn’t make any appreciable difference to the mix. Going a little further with the subtle black variations by reducing the cyan and increasing the magenta in the rich black mix will produce a relatively warm tone in the black, while going the other way makes a colder, bluer black.

But there are other ways to print invisibly. At the basic level, how about black on black? This could be black ink (or toner) onto black paper; the difference between the two black tones – ink and paper – will normally be not be so clear that it is obvious on first glance, but still be enough to detect on closer examination. You can achieve the same kind of result on normal plain paper with a ‘single colour’ black and a rich black. The first is what you get by printing just with the black plate in commercial four-colour offset work, or with just the black cartridge in an inkjet printer, if your device’s print driver doesn’t override how colour is output. It is black, but not a truly dense, velvet-at-midnight black. The second, a rich black, is made from black plus equal amounts of the other inks as well, specifically the magenta and cyan. Process yellow is actually pretty weak, so it doesn’t make any appreciable difference to the mix. Going a little further with the subtle black variations by reducing the cyan and increasing the magenta in the rich black mix will produce a relatively warm tone in the black, while going the other way makes a colder, bluer black.

Printing with varnish is another useful way to add ultra-subtle detail to something. This can be used to make a kind of white-on-white print, or to overlay something on a detailed, distracting design printed in normal visible colours. Using matte and gloss varnishes gives even more control, although it adds yet another ink to the print specification. In most cases the results will be all but invisible unless light hits it at the right angle.

The trouble with these old tricks is that while they’re useful for dome things the results aren’t really invisible. They’re hard to see, but you don’t need special conditions or processes to see what’s printed.

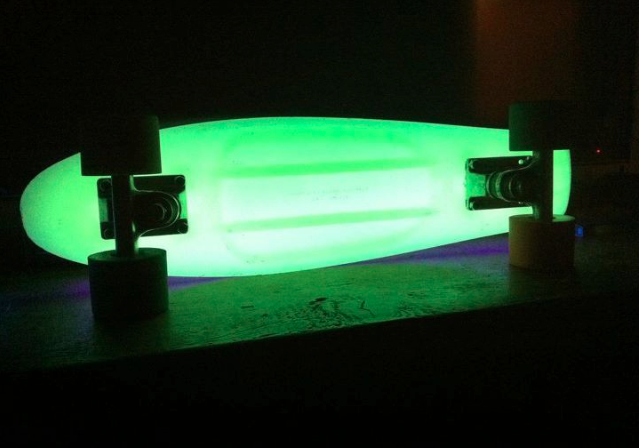

While looking around for different options I found something rather unexpected and much more along the lines of real invisible ink. It is possible to get UV ink that fluoresces in ultraviolet light but really is essentially invisible in normal light. Better still, from the point of experimenting and making proofs and mockups, this isn’t just something that commercial print companies buy in for press work – you can also buy UV ink in cartridges for desktop inkjet printers.

A simple Google search will throw up a few suppliers, mixed in with misleading references to UV-cured and UV-resistant pigment inks. UVstuff.com isn’t ideal for us in the UK as it’s based in the US, but it has a short video showing an inkjet printer churning out a UV-printed page, with a hand-held UV lamp revealing the image when it is passed over the printer’s output tray. (In case you’re worried, a ‘black light’ UV lamp generates relatively long-wave UV radiation, not the kind of UV that is known for suntans and DNA damage. Although in the absence of actual medical advice – I’m a technical editor, not a doctor – I’d avoid unnecessary repeated, very prolonged exposure.) More UK-specific sources include inkribbonpaper.co.uk and iographics.co.uk, but check with your current supplier too.

One particularly striking thing with this example is how the result is, to an extent, in full colour. UV ink works by absorbing a high-energy wavelength of light, in the invisible ultraviolet range, and emitting it in a lower, visible wavelength. The colour that is emitted depends entirely on what wavelength the ink produces – hence different inks for creating different fluorescent colours. Curiously, the way white is produced in a print is through white UV ink. Plain paper (without optical whiteners) will be dark under UV light, so you need to print the white areas and leave the black areas unprinted.

I haven’t ordered my UV supplies yet so I’m going on theory rather than experience here, but I imagine that using the white UV ink cartridge in place of the black, then inverting a CMYK-mode image in Photoshop and rotating the hue by 180 degrees to bring the colour back to normal could produce a workable result. But I’m sure there’ll be oddities to deal with. In practise, this stuff will probably be far more useful for printing invisible graphics and text rather than photographic images – but experimentation is always good, right? Especially before committing to a long print run. That’s standard good practise for any kind of new method, whether for print or screen production.